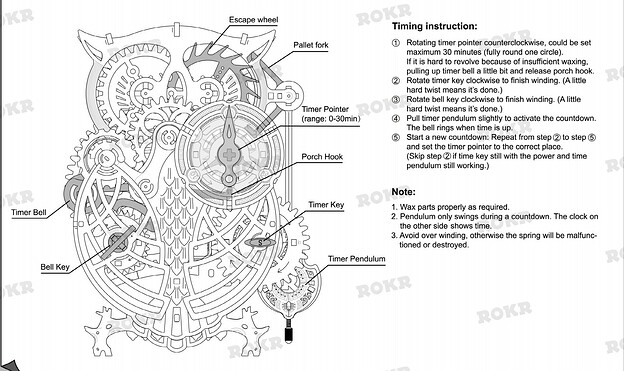

Assembly Instruction

FAQ

Owl Clock-LK503

(Click the pictures to view in full size)

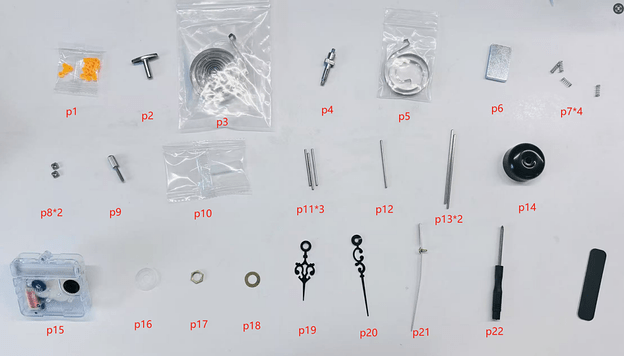

Parts Problem

2.B20 is a fragile part and can be replaced.

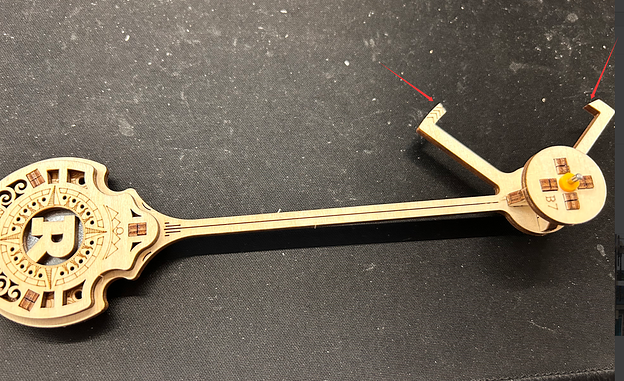

3.The pendulum cannot swing normally:

①Check if the assembly steps are correct.

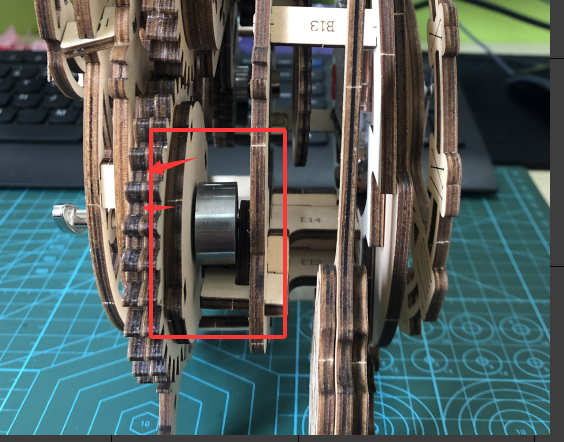

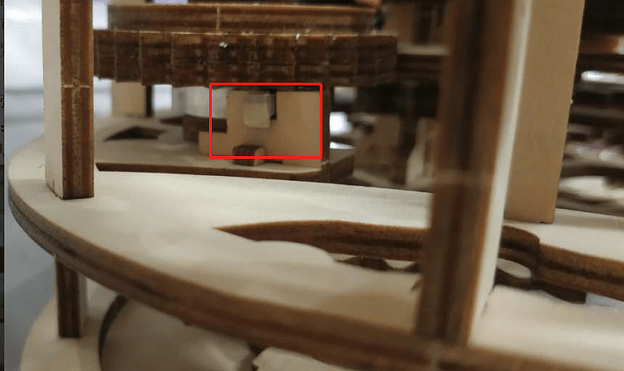

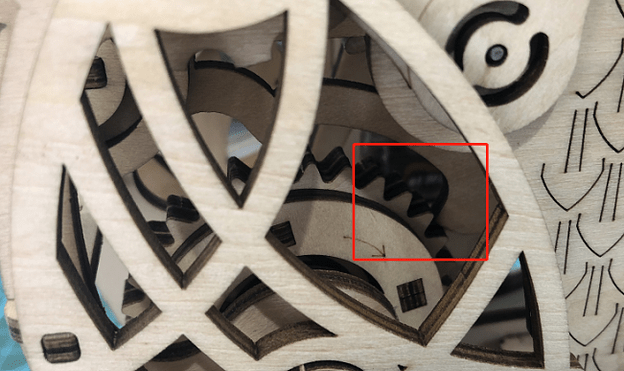

②The friction between the escape fork 620 and Part E1 is too large.

Solution: Wax them. The red circle position as shown in the picture can be sanded smooth with sandpaper.

③Check if the spring is twisted to the end. Wind the spring fully.

4.The alarm does not ring.

①Check if the assembly steps are correct.

②Check if the hook of small spring is hooked to the wooden board.

③Check if the back hook is hooked to the gear wooden board.

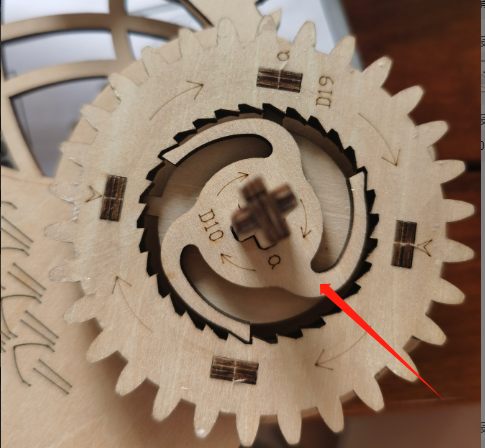

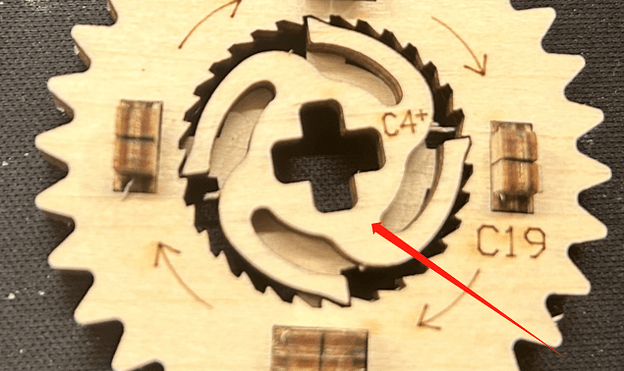

④Check if the directions of D10 and C4 are right.

⑤Check if the clock is placed on a horizontal surface.