Assembly Instruction

FAQ

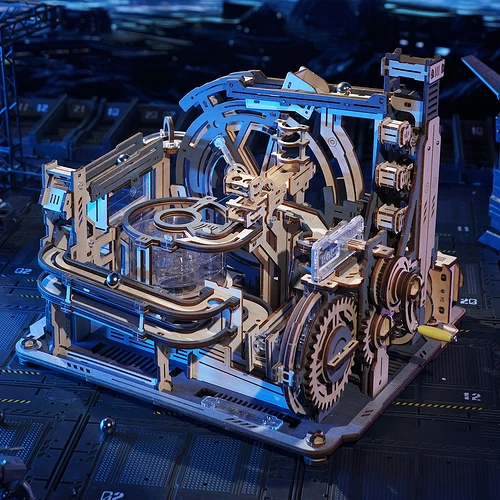

Marble Spaceport -LGC01

(Click the pictures to view in full size)

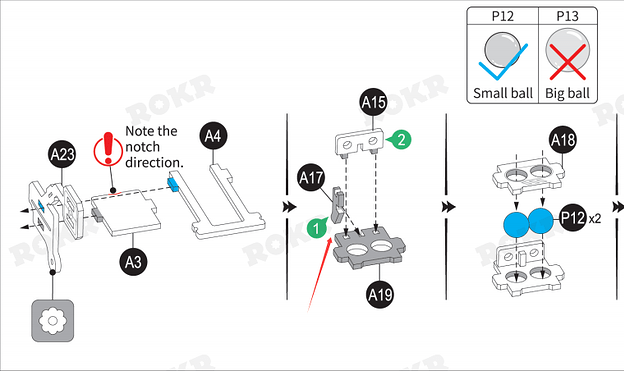

Assembly problems causing ball jamming and gear non-rotation due to ball jamming

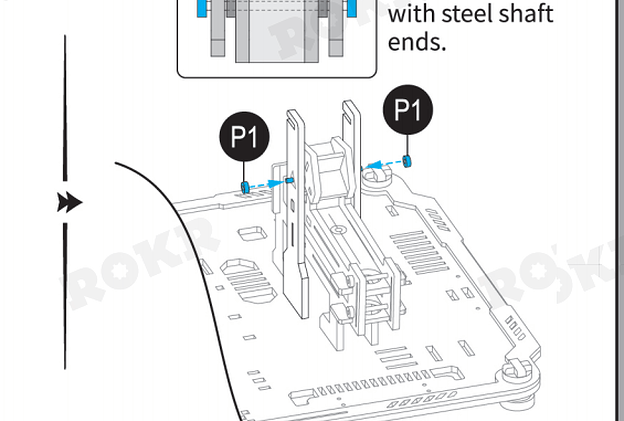

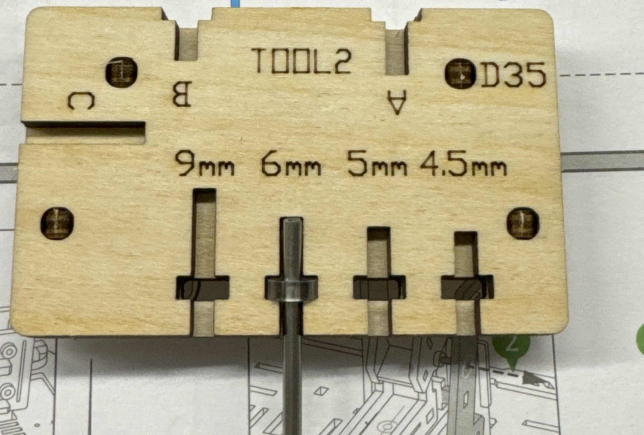

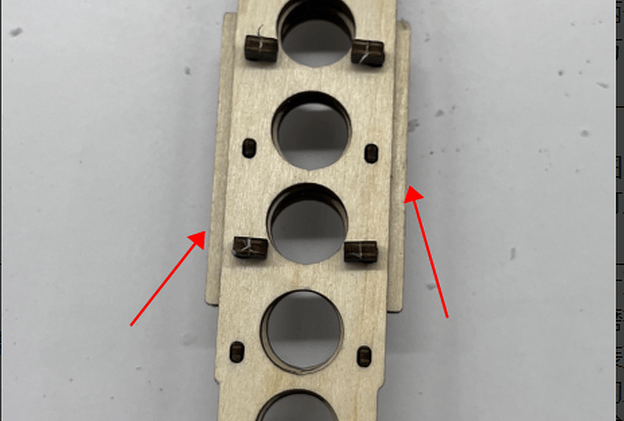

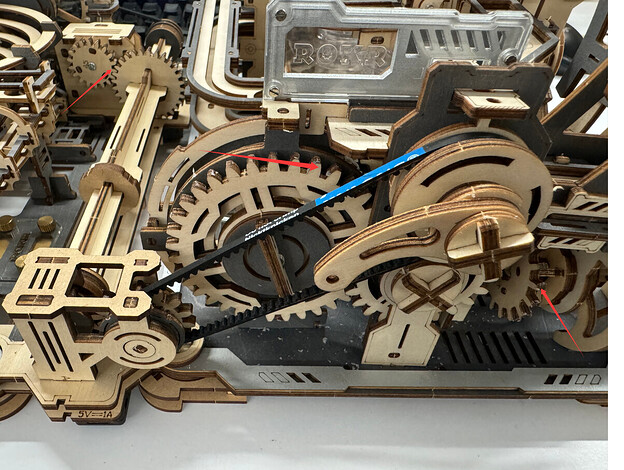

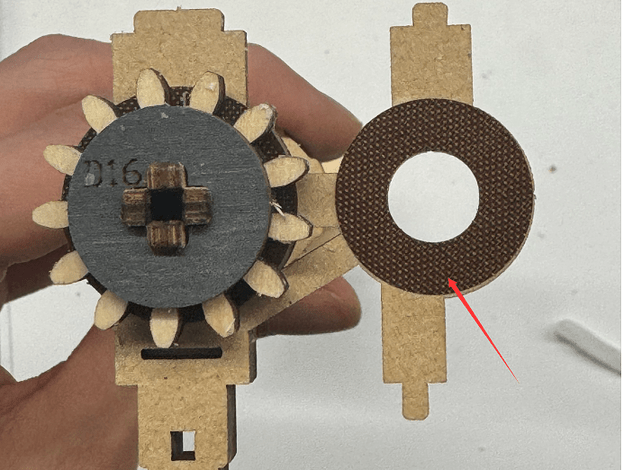

- The bushing is not pressed flush or is too tight on Page 4, causing ball jamming in this step: Use auxiliary tool to press the bushing to control the distance.

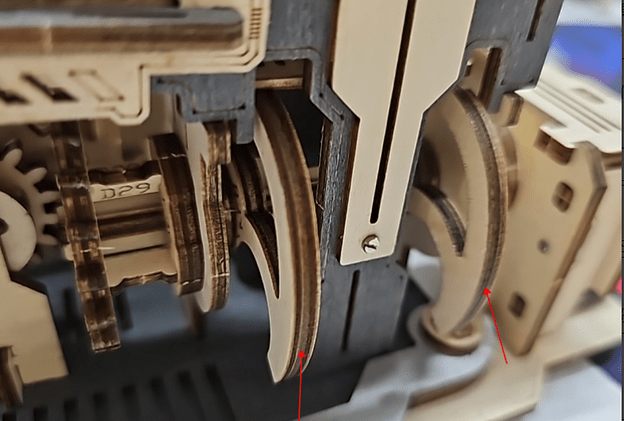

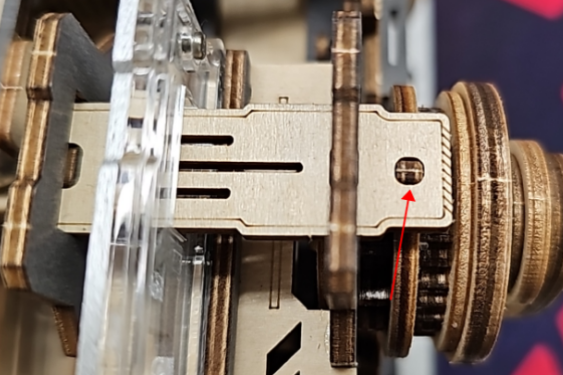

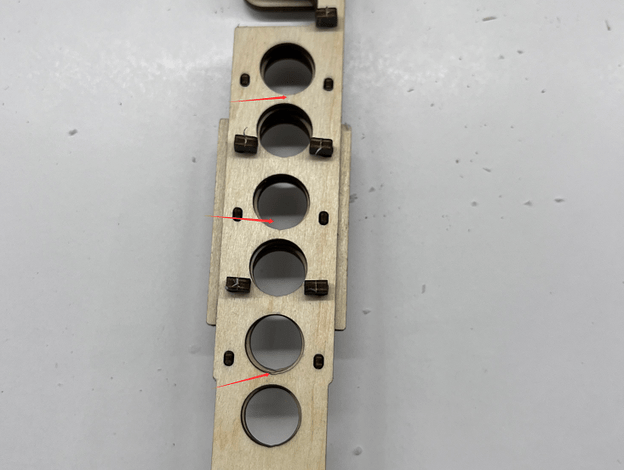

2.Check if the parts are polished and waxed as shown in the arrow position.

3.Polish and wax the parts on the test position again on Page 10.

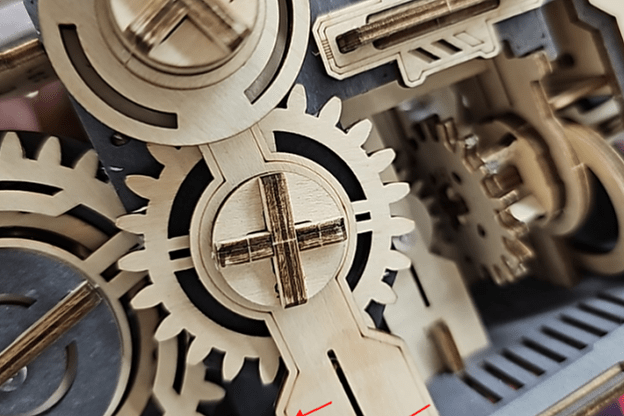

Check if the direction of Part K28 is right and the parts are waxed:

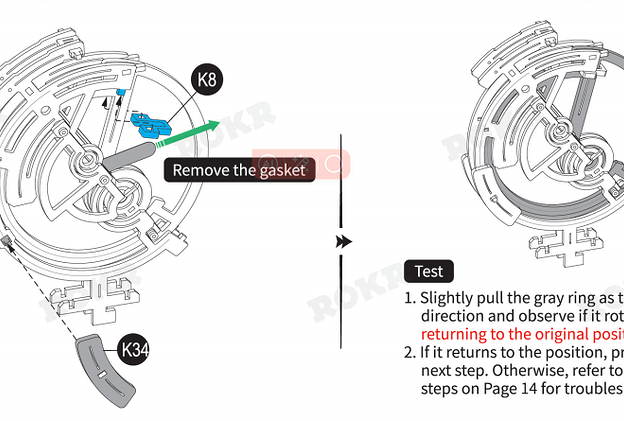

4.The ring in Step 8’s test cannot rotate freely and return automatically.

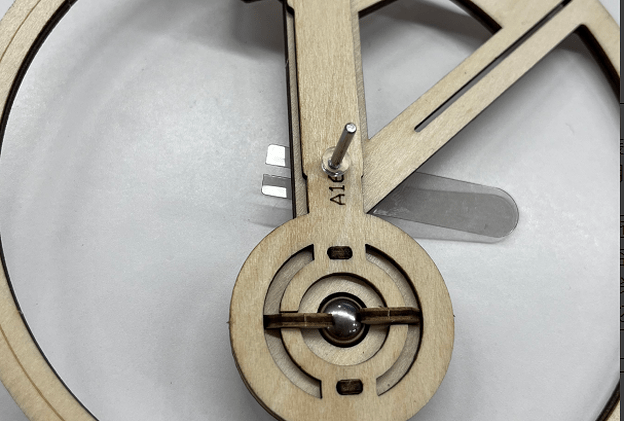

①Check the position of A16 is right.

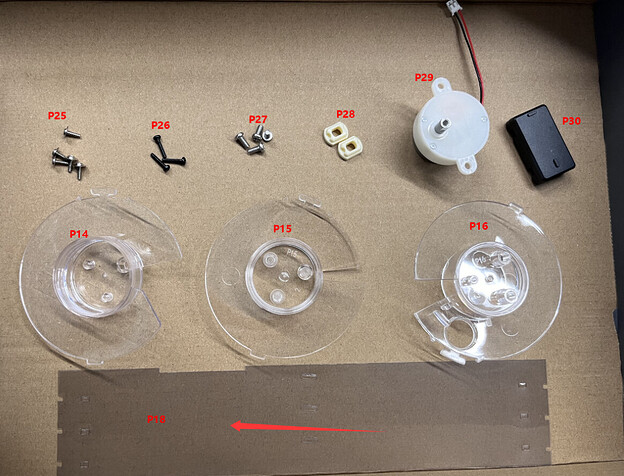

②Check if Gasket P5 and Auxiliary Tool 2 are used to assemble bushings.

③Check the position of E7 is right.

④Check the small steel balls in the middle are misused or missing.

Press the bushing flush.

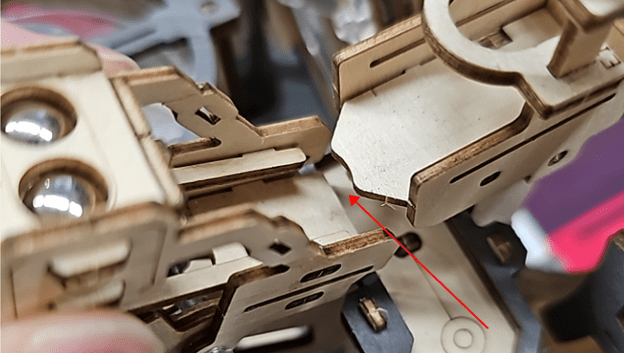

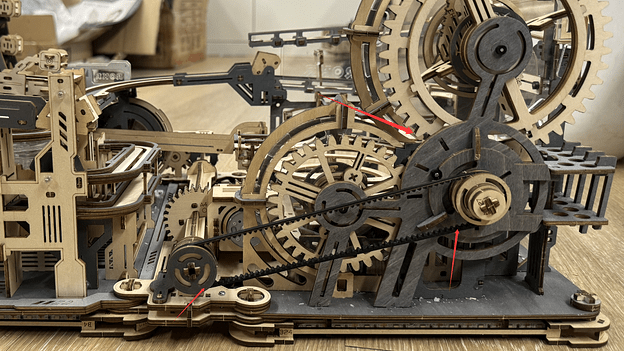

Ball jamming and non-rotation problems after assembly

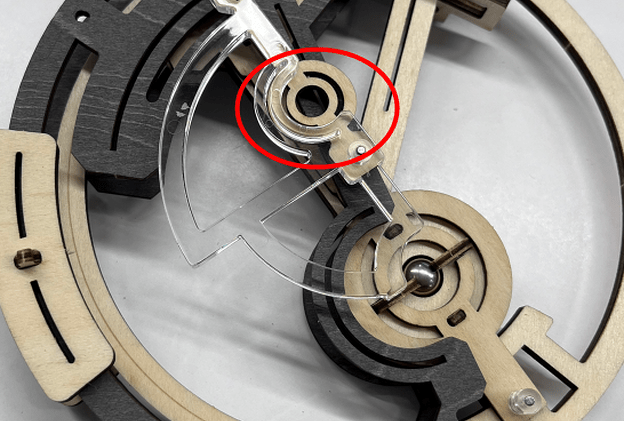

- The ball is stuck at this position as shown in the picture.

The hole here is too small.

First, sand the hole with sandpaper. If not, replace Part H5.

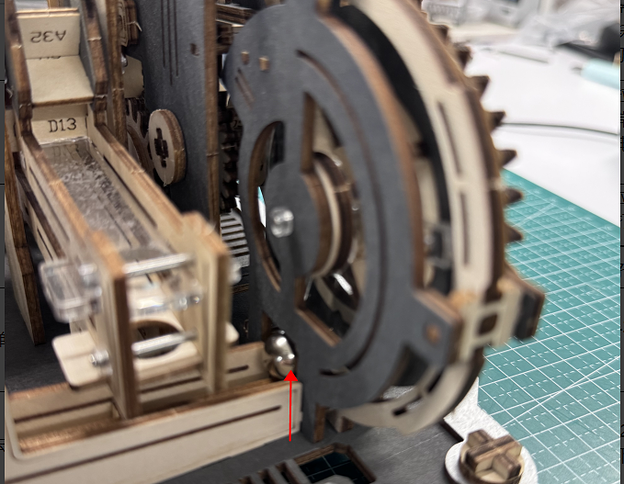

3.The ball is stuck at the arrow position as shown in the picture.

Check if the hole position of A28 is at the bottom or polish the bottom of A17 with sandpaper.

4.The diversion structure - the chair rebounds automatically after going down.

Replace Part B11, B14, and K43.

- There is resistance during operation or the rotation speed is uneven in electric mode.

Check if Part D7 is assembled reversely.

The correct assembly position has an indentation surface, if not, the reversed one has no indentation surface, and the hole direction is also reversed.

Solution: Enlarge the D10 hole; it is not recommended to remove and reassemble.